MARSHALL BAHEN

Renewable Technology Challenge

In this project we were tasked with designing a wind turbine blade. The focus of the project was on material selection, and selecting the best material for a given situation, all while minimizing deflection to be less than 10mm. Each team was assigned one of four scenarios that had different objectives, constraints, and functions.

Design Process

After completing an initial research memo, we drafted an initial problem statement for a wind turbine, followed by an objective tree for one of the four different scenarios.

After refining our problem statement for the wind turbine, using information gathered from the project module. We then drafted a problem statement specifically for the turbine blade.

Using our assigned scenario The Roof Generator we refined our objectives, functions, and constraints using details from the project module specific to the assigned scenario.

We then decided on the top three objectives and came up with metrics to evaluate these objective by:

-

Diameter of blade assembly should be minimized

Unit: Diameter in meters -

Blade assembly should be cost-effective

Unit: Cost per blade assembly -

Blade assembly should be lightweight

Unit: Mass of blade assembly in kilograms

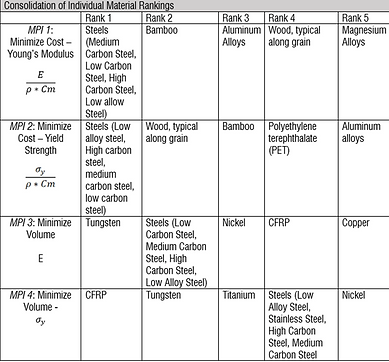

Using the objectives we found in the previous milestone, we chose Material Performance Indices (MPI) that would allow us to select the optimal materials for our design scenario. We then plotted the MPIs in Ansys Granta Edupack and selected five materials each with the highest index value for our given MPI. The MPI I selected was minimize cost, to achieve this result I plotted Young's Modulus (E) vs Density (p) multiplied by Cost (Cm)

We then selected our top 3 overall material finalists

-

Low Alloy Steel was selected due to its excellent material characteristics. Low alloy steel was present in the top 5 of all four MPI plots. It performed exceptionally well due to its high Young's Modulus and Yield Strength, as well as low cost. The main detractor from Low Alloy Steel's performance is its high density.

-

Aluminum Alloys performed very well in two of the four MPIs. They performed well because they have moderately high Young's Modulus and Yield Strength, while having lower density than steel. The main detractor from Aluminum is that it is almost 3 times as expensive as low alloy steel.

-

Carbon Fiber Reinforced Polymer (CFRP) performed very well in two of the four MPIs, due to its high overall Yield Strength and Young's Modulus. CFRP has a much lower density than either Aluminum Alloy or Low Alloy Steel. However, this performance comes at a cost. CFRP is almost 50 times more expensive than low alloy steel.

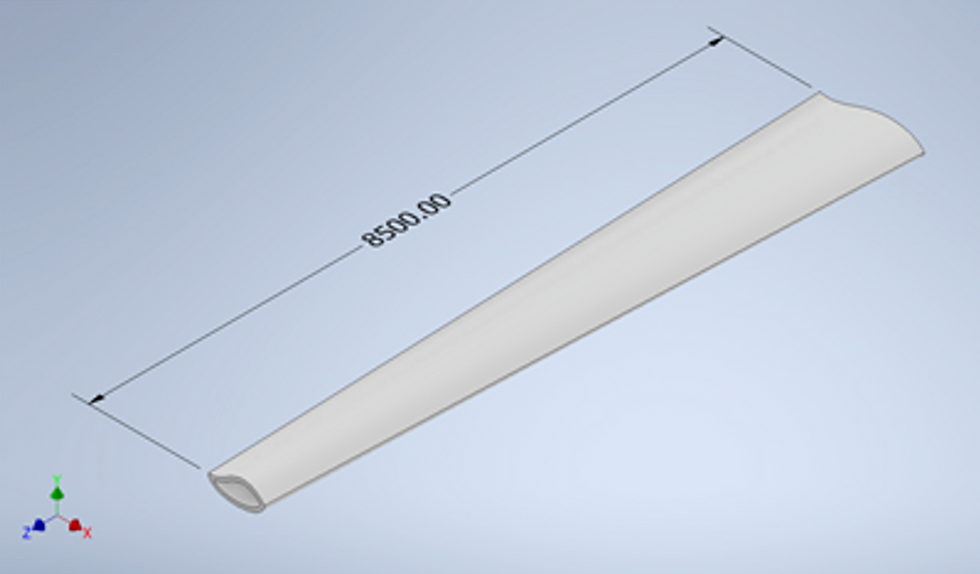

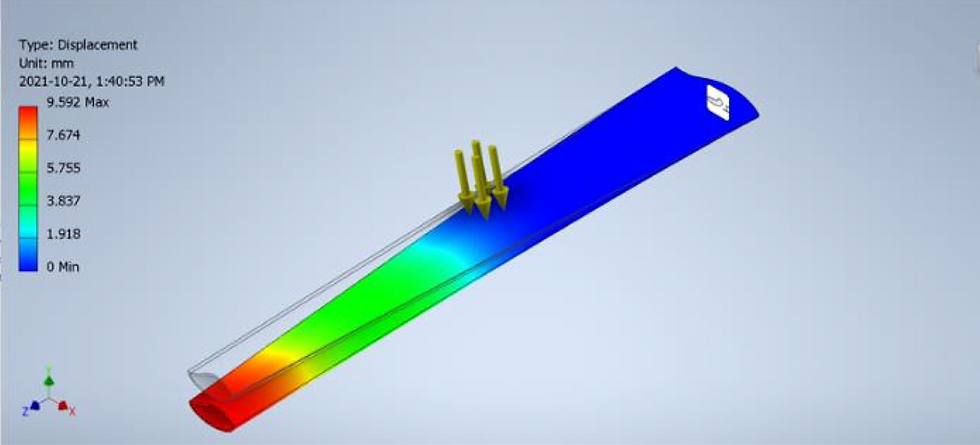

We completed a calculation by hand to estimate the deflection of the turbine blade. We then followed instructions to produce a CAD model in Autodesk Inventor of a turbine blade with set dimensions. Using this model we performed a deflection simulation using the same provided numbers from the hand calculation

We completed the same deflection calculations by hand, however we each chose a different thickness for the turbine blade, and used the Young's Modulus value of our chosen material: Low Alloy Steel. In this way we found an approximate range for the thickness of the blade necessary to obtain a deflection value between 8.5 and 10mm.

Then using our CAD model in Autodesk Inventor we performed multiple deflection simulations, varying the thickness of the blade to get the deflection within the range. We found that the optimal blade thickness for our material Low Alloy Steel was 26mm, which resulted in a maximum deflection of 9.592m

Key Skills

1. Engineering Design Principles: Functions, Objectives, and Constraints In this project I learned the importance of reading the project module to extract as much possible information about the objectives, functions and constraints at the beginning of the project. 2. Material Properties and Selection Processes Throughout the course of this project I learned a lot about the different mechanical and general properties of materials, as well as how they correlate to each other and the importance of specific properties to achieving different solutions. 3. Autodesk Inventor - Modelling Techniques and Finite Element Analysis 4. Ansys Granta Edupack - Plotting Material Properties and Indices 5. Calculating Deflection using Youngs Modulus and Moment of Inertia 5.1 Python Deflection Calculation Program I wrote this Python program to calculate deflection from a given thickness input. This allowed me to calculate different deflections very quickly and allowed me to modify variables at will. This made Project 1 Milestone 3A much easier because I was able to double check each group members hand calculations, and get a rough idea of the optimal thickness for our blade.

Summary

At the end of this project we wrote a report summarizing the results of our project and what we had learned. We wrote a finalized problem statement, and identified additional considerations that were outside the scope of the project but may be worth investigating in the future. We wrote a justification of our technical objectives and material performance indices, and discussed how we came up with our objectives and MPIs. We justified our selected material, referring to our Granta Edupack plots. We justified our CAD modelling and deflection simulation using pictures of our simulation. Finally, we wrote a conclusion, where we discussed our results and how we would investigate additional considerations if given the opportunity. Please see our full Design Summary below for more information.